Sandpaper Grit Chart

The sandpaper grit chart is a comprehensive guide used to determine the coarseness or fineness of sandpaper, which is essential for various tasks such as woodwork, metalwork, and drywall finishing. The grit chart is a standardized system that measures the abrasive material's size and spacing on the sandpaper, allowing users to select the right grit for their specific needs. In this article, we will delve into the world of sandpaper grit charts, exploring their importance, applications, and providing an in-depth analysis of the different grit ranges.

Understanding the Sandpaper Grit Chart

The sandpaper grit chart is based on the ANSI (American National Standards Institute) standard, which categorizes sandpaper into different grit ranges. The grit range is measured in terms of the number of abrasive particles per square inch of sandpaper. The higher the grit number, the finer the sandpaper and the smaller the abrasive particles. Conversely, lower grit numbers indicate coarser sandpaper with larger abrasive particles. The sandpaper grit chart typically ranges from 60-grit (very coarse) to 1200-grit (very fine).

Grit Ranges and Applications

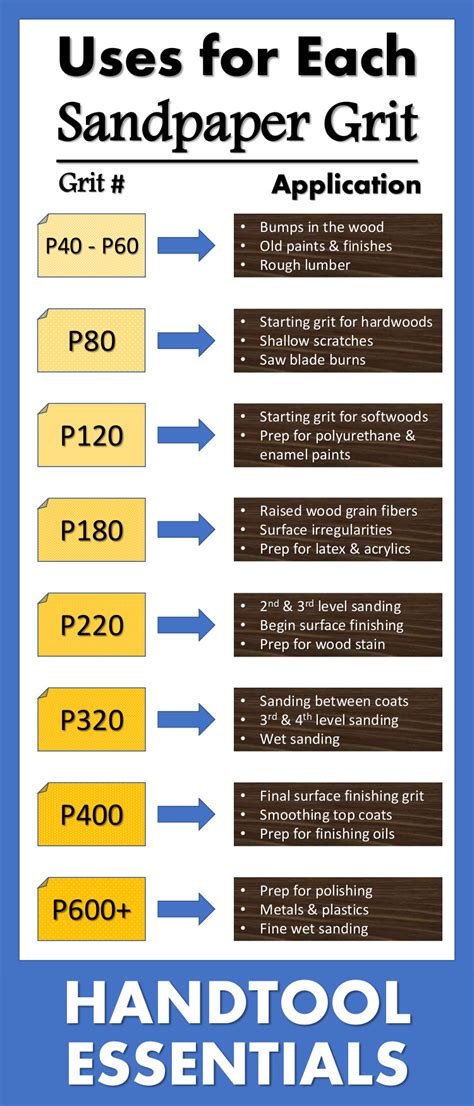

The sandpaper grit chart can be broadly divided into several ranges, each with its specific applications and uses. The main grit ranges include:

- Coarse grits (60-100): Used for heavy stock removal, rough shaping, and removing old finishes. Coarse grits are ideal for tasks such as sanding down wood, metal, or drywall to prepare them for further processing.

- Medium grits (120-220): Suitable for general-purpose sanding, smoothing out surfaces, and removing minor imperfections. Medium grits are commonly used for sanding wood, metal, and drywall, as well as for preparing surfaces for painting or finishing.

- Fine grits (240-320): Used for fine-tuning surfaces, removing minor scratches, and creating a high-gloss finish. Fine grits are ideal for tasks such as sanding wood, metal, or drywall to create a smooth surface for painting or finishing.

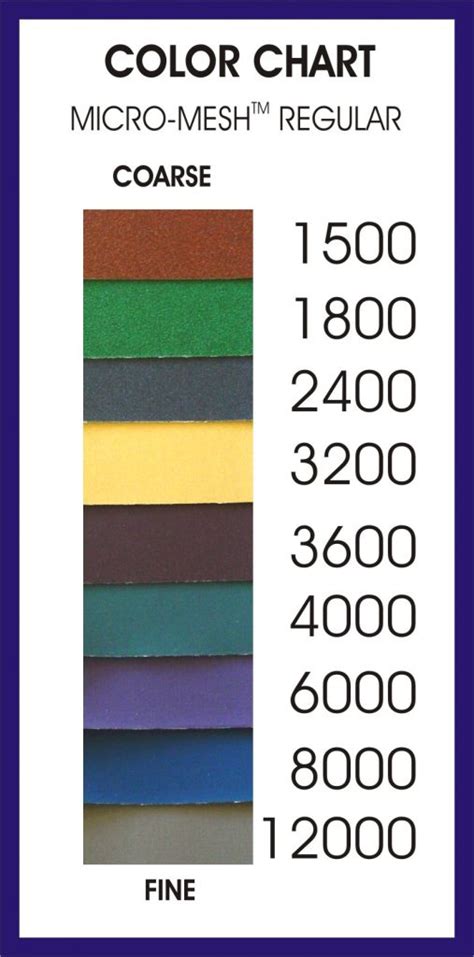

- Extra-fine grits (400-600): Employed for polishing and creating a mirror-like finish on surfaces. Extra-fine grits are commonly used for tasks such as polishing metal, glass, or ceramic surfaces.

- Ultra-fine grits (800-1200): Used for final polishing and creating a high-gloss finish on surfaces. Ultra-fine grits are ideal for tasks such as polishing wood, metal, or drywall to create a smooth, reflective surface.

| Grit Range | Application |

|---|---|

| 60-100 | Heavy stock removal, rough shaping |

| 120-220 | General-purpose sanding, smoothing out surfaces |

| 240-320 | Fine-tuning surfaces, removing minor scratches |

| 400-600 | Polishing, creating a mirror-like finish |

| 800-1200 | Final polishing, creating a high-gloss finish |

Technical Specifications and Performance Analysis

Sandpaper grit charts also provide technical specifications and performance analysis for each grit range. These specifications include the abrasive material, backing material, and bond strength, which affect the sandpaper’s performance and durability. For example, aluminum oxide abrasive is commonly used for wood and metal sanding, while silicon carbide abrasive is often used for drywall and paint sanding.

Performance analysis is critical in determining the sandpaper's effectiveness in removing material, creating a smooth surface, and minimizing scratches. Factors such as sanding speed, pressure, and direction can also impact the performance of the sandpaper. By understanding the technical specifications and performance analysis of each grit range, users can optimize their sanding process and achieve the desired results.

What is the difference between open-coat and closed-coat sandpaper?

+Open-coat sandpaper has a more spaced-out abrasive pattern, allowing for better dust extraction and reduced clogging. Closed-coat sandpaper has a more dense abrasive pattern, providing a smoother finish but potentially clogging more easily.

How often should I replace my sandpaper?

+Sandpaper should be replaced when it becomes worn out or clogged, as this can affect its performance and lead to poor results. The frequency of replacement depends on the specific application, material being sanded, and sanding technique.

Can I use sandpaper on wet surfaces?

+It’s generally not recommended to use sandpaper on wet surfaces, as this can lead to uneven sanding, scratches, and damage to the surface. However, some specialized sandpaper, such as waterproof sandpaper, can be used on wet surfaces, but it’s essential to follow the manufacturer’s instructions and take necessary precautions.